In today's increasingly refined home decoration and construction projects, seemingly insignificant small accessories often determine the success or failure of the entire project. Among them, " drywall screws " is such a humble but vital basic building materials. It not only improves the stability and durability of the wall fixation, but also provides an efficient and convenient solution for professional construction personnel and home DIY users.

Uncover the mystery of drywall screws: why it is an invisible hero in modern decoration

Many people tend to ignore the role of small screws when starting home improvement projects, but in fact they are like the "behind-the-scenes director" of the architectural world, silently supporting the safety and beauty of every piece of gypsum board, partition panel and even the whole wall. Compared with the wooden nails used in traditional wooden structures, the drywall screws have a stronger bite force on the lightweight board through a special thread design, which greatly improves the reliability of the overall system.

From theory to practice: How drywall screws achieve super-strong fixation of lightweight walls

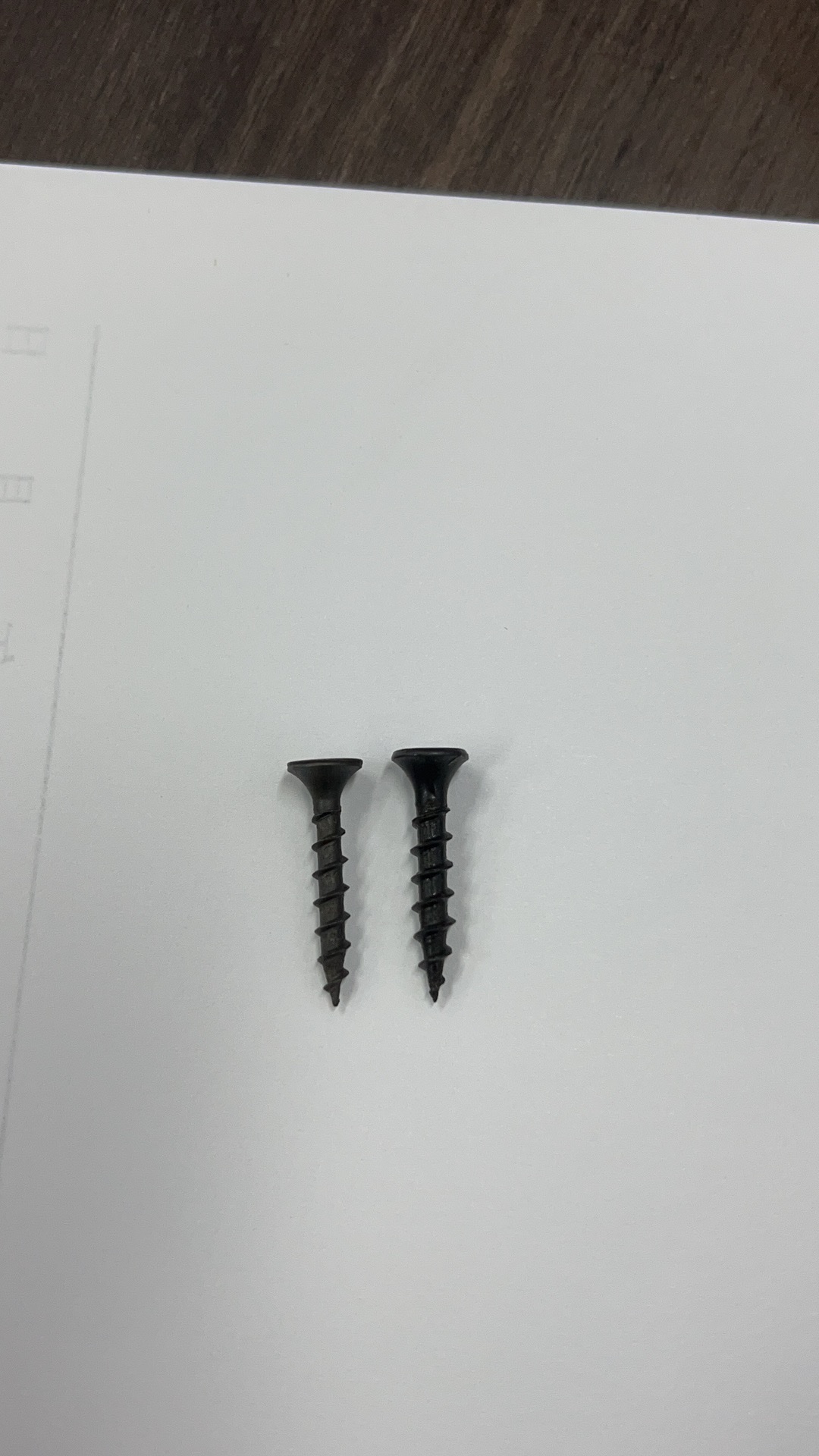

The core of the drywall system is to ensure both strength and flexibility. This is where drywall screws stand out-their unique double-groove thread structure can evenly apply force during the screwing process to prevent the plate from cracking due to excessive local pressure. At the same time, this design also enhances the anchoring ability, making the connection tighter and firmer, and maintaining long-term stability even in the event of vibration or temperature changes.

Material determines strength: what core competitiveness does high-quality steel give drywall screws?

Truly high-quality drywall screws are usually made of cold-rolled carbon steel and are supplemented by galvanized or other anti-corrosion coatings to greatly improve oxidation and corrosion resistance. These products perform well even in humid or dusty environments, greatly extending their service life while reducing maintenance costs.

Not just nails: the essential difference between drywall screws and ordinary screws

Many people mistakenly think that as long as it is a metal screw can be used to install gypsum board, but in fact there are essential differences between the two. Due to the lack of special thread design and protection mechanism for fragile substrates, ordinary screws can easily cause problems such as slipping and perforation, and in severe cases, they can also cause safety hazards. The specially developed and produced drywall screws are perfect to avoid these risks and become the preferred standard configuration recognized by the industry.

Home improvement talent's secret weapon: diversified application of drywall screws in DIY projects

For friends who are keen to transform their living space, it is important to have the right tools. Whether hanging picture frames, assembling storage racks or building simple compartments, drywall screws make it easy for a variety of tasks. More importantly, it has a low operating threshold and a high success rate. Even beginners can complete the ideal reinforcement operation at one time.

Professional-level construction: Why do architects love drywall screws?

Experienced workers know that time is money. The reason why they prefer to use drywall screws, in addition to valuing their durability, another big reason is that they are extremely efficient. With the help of an electric screwdriver, a screw can be driven into the work in a few seconds, which greatly saves physical consumption and speeds up the overall progress.

Save time and effort: how drywall screws make tedious projects get twice the result with half the effort

in the face of hundreds of tasks that need to be assembled one by one, it is obviously difficult to meet the needs of modernization if we continue to use the old method. With the help of high-performance drywall screws, the synchronous propulsion mode of measuring and fixing can almost be achieved, which significantly reduces the probability of rework and makes on-site management more orderly.

Selection Guide Open: Which Key Factors to Pay Attention to in Selecting Durable and Reliable Drywall Screws

the dazzling array of products on the market is dizzying, so how should we distinguish the advantages and disadvantages? First of all, we should pay attention to whether the brand reputation is good and whether there is a formal quality inspection report. Secondly, we should check the appearance for burrs and deformations. Finally, we should confirm that the packaging marking information is complete and accurate, such as the specification length and other contents must be clear and easy to find and replace spare parts in the future.

the mystery behind dimensions and specifications: how to accurately match screw models for different types of engineering projects

generally speaking, it is recommended to choose a flat head type with a length of about 25mm for regular household use. However, for commercial use or large-scale renovation plans, it may be necessary to consider professional-grade styles that are stronger (for example, over 4mm in diameter) and have self-tapping tips. Reasonable matching can play the maximum effectiveness.

Future home trend accessories: the adaptability of drywall screws in new building materials

With the concept of green energy saving deeply rooted in the hearts of the people, more and more innovative composite sheet into the market. It is gratifying that the new generation of improved drywall screws has been able to adapt well to a variety of new material systems including calcium silicate board, ALC autoclaved aerated concrete, etc. This means that the future world of interior decoration will usher in more possibilities and development potential.