Fine design: ideal for various fixed needs

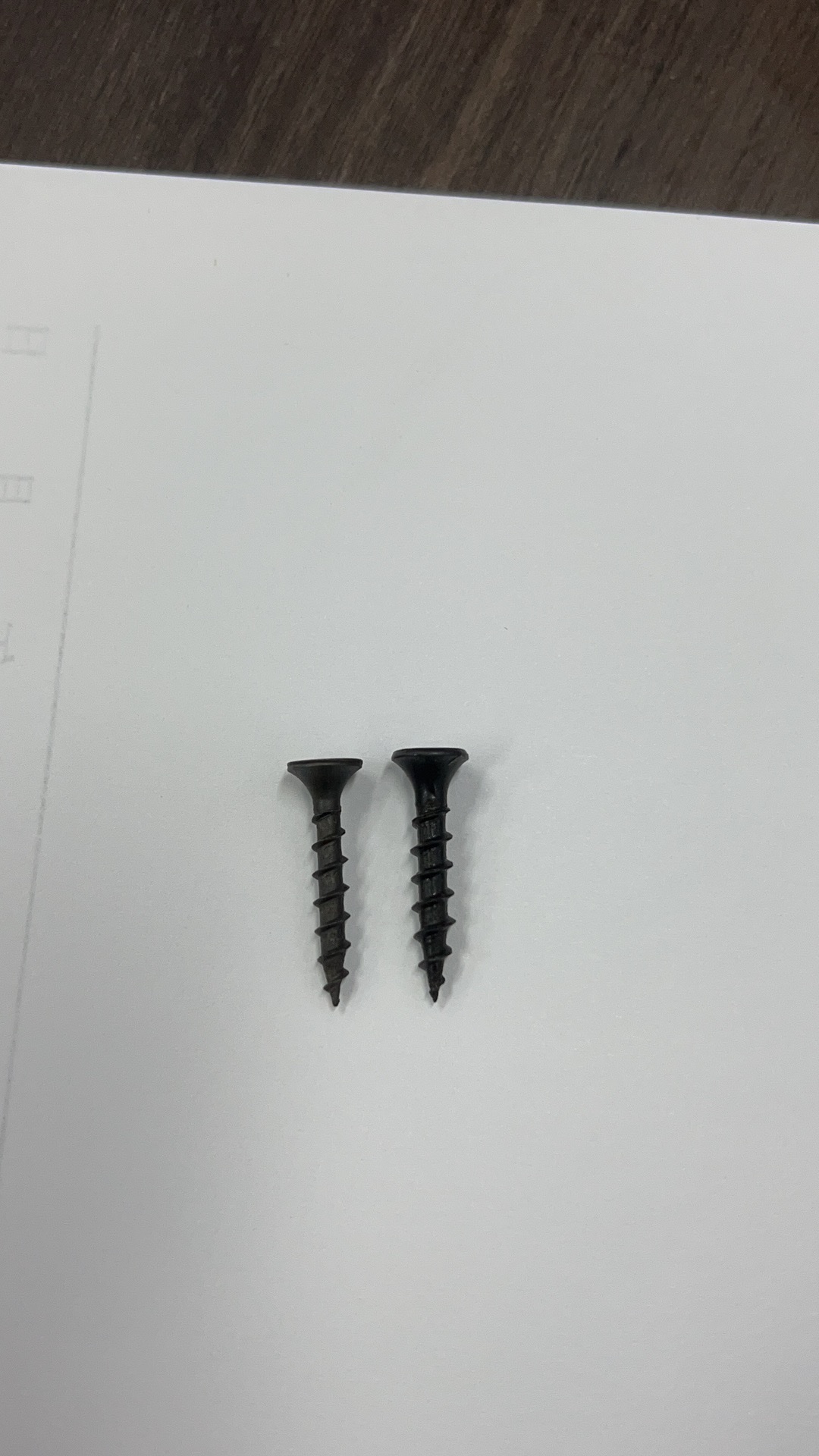

Drywall screws have become the heart of many construction and decoration companies, first of all due to its carefully designed features. Each screw is equipped with a sharp thread and a strong head structure, which allows them to easily penetrate gypsum board and other lightweight building materials and lock firmly. This strong grip ensures the safety and stability of the wall structure.

Not only that, there are many types of drywall screws on the market to choose from, such as common cross-recessed and flat head screws, and more professional hexagon head screws. The difference between different types lies in the working environment and special requirements. For example, flat head screws are often more suitable where frequent disassembly is required; for areas with higher load-bearing requirements, hexagon head screws with higher torque tolerance can be selected.

Different types of drywall screws are suitable for different application scenarios

Different types of drywall screws are suitable for different application scenarios

Multipurpose applications: everything from home improvement to commercial projects

Whether it's a renovation in a welcoming family home, a major renovation in a modern office building, or a complex ceiling system in a bustling mall-drywall screws always find their way. Especially in the kitchen cabinet installation such meticulous work, it can quickly and accurately assemble the various components, greatly improving the work efficiency.

In large public places such as station halls, shopping centers and other landmark construction projects, drywall screws are also widely used. For example, it is used to hang heavy lamps or signs, which can perform well even in the face of large weight loads, demonstrating the huge energy and unlimited potential behind this small object.

Drywall Screws Help All Kinds of Renovation Projects

Drywall Screws Help All Kinds of Renovation Projects

Simplified Construction: Make Professional Work Easy

For people engaged in interior decoration, drywall screws are not just a simple connecting part, but more like their right-hand man. Compared with the traditional method of using iron nails or plastic expansion pipes, drywall screws have their own pre-drilling function, which greatly reduces the time cost of manual drilling. More importantly, due to its special spiral shape, it is not easy to cause the plate to crack and damage, and the integrity of the material is protected.

Especially when working with power tools, the advantages of drywall screws are more obvious. With just one tap of the start button, you can complete a perfect fixed task in a few seconds. Even novices who are first exposed to this work do not have to worry about the difficulty of operation, because in most cases, they only need to follow the basic steps in order to complete the whole process smoothly.

Quality Assurance: Build a durable space environment

A good drywall screw is not only won by appearance, but more importantly, whether it can stand the test of time. High-quality steel and advanced processing technology are the two magic weapons to create reliable products. Every detail is strictly controlled, and strive to achieve excellence, so as to ensure that every component can withstand the pressure of long-term load without deformation and fall off.

With these excellent characteristics, high quality drywall screws can not only bring stronger safety protection performance to buildings, but also facilitate later maintenance work. In addition, many well-known brands will also provide corresponding quality assurance certificates and related industry certification documents to increase users' trust in the performance of their products.

Selection Guide: Key Elements for Selecting the Best Model

In the face of a wide variety of market options, how can you choose the best drywall screw for your project? Here are a few simple and easy principles to help you make an informed decision:

The first thing to consider is the thickness of the wall. Generally speaking, the screw length required for thicker walls will be relatively longer. The second is to pay attention to the parameter marking information on the packaging box, especially the tensile strength index, which is one of the important criteria to measure the bearing capacity of a screw. If you think it doesn't matter if you can't remember too much professional knowledge, the following table lists the recommend ranges corresponding to several commonly used sizes for reference:

| Drywall Screws | |

|---|---|

| Applicable Scenarios | recommend specifications |

| Ordinary room | 30mm - 50mm |

| Waterproof area of bathroom | 50mm - 70mm (moisture-proof type) |

| Outdoor Balcony Railing | 70mm or more (stainless steel) |

Safety Tips: Some Reminders for Correct Use

Although drywall screws themselves may seem trivial, improper use can lead to safety hazards and even the risk of accidents. Therefore, be sure to read the enclosed instructions carefully and perform the operating procedures strictly in accordance with the instruction manual. Try not to change the quantity and location arrangement specified in the original design scheme at will, so as not to affect the overall structural stability.

regular inspection has been fixed parts of whether there is any abnormal situation is also one of the necessary preventive measures. Once the problem is found, it shall be corrected and restored by appropriate means in a timely manner. Finally, don't forget to properly keep the unopened product packaging accessories to prevent oxidation and rust caused by exposure.