Why do you say that drywall screws are the secret weapon of decorators?

In the process of home improvement, many people often only focus on the overall aesthetics and functionality, but often ignore the most basic structural stability. In fact, a small negligence may cause furniture to loosen, wall damage, and even bring serious safety hazards.

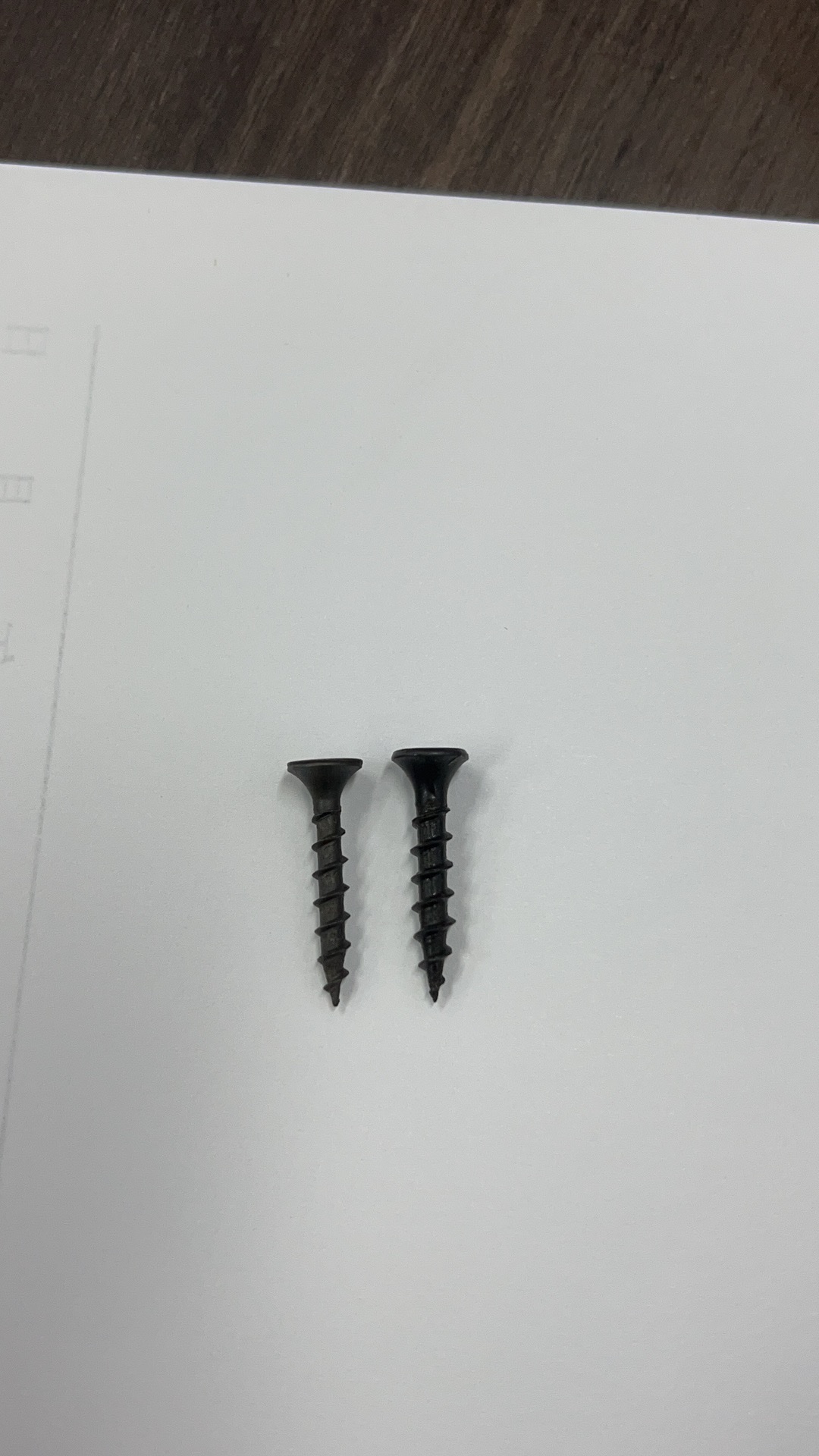

Drywall screws are professional fasteners for this type of problem. They are developed and manufactured for complex wall environments and can be flexibly adapted to a variety of materials, including common gypsum boards, concrete walls and other non-standard surface substrates. Whether you are installing bookshelves, hanging paintings, or fixing heavy equipment, this highly adaptable product always provides "invisible" support and silently guards the bottom line of home safety.

Uncover the technical code behind the drywall screw

Different from ordinary self-tapping screws on the market, drywall screws adopt more advanced tooth grain structure technology and anti-oxidation coating technology, which can significantly extend the actual service life of the product on the basis of greatly improving the initial embedding force.

By accurately measuring the screw-in angle and tooth depth, engineers can quickly establish a firm occlusal relationship even when facing thick layers or porous media, realizing an efficient plug-and-play assembly experience. Behind every subtle design change is the persistent pursuit of quality and safety.

High-strength steel for ultimate load-bearing performance

Forged from selected industrial grade alloy steel, it has excellent tensile strength and seismic resistance, even if it is suspended by hundreds of pounds of heavy objects.

Anti-aging design is not afraid of wet and harsh conditions

After multiple anti-corrosion treatment, it can run stably in high humidity environments such as toilets and basements for a long time, is not easy to rust and deform, and always maintains good working conditions.

Analysis of purchasing skills from a practical perspective

It is not easy to select the best drywall screws for your project. In addition to the appearance size, you also need to consider factors such as wall type (such as whether it is hollow brick), expected load size and required anchor bolt specifications.

It is recommended that first-time users can assist in the decision-making process by viewing the parameter comparison table provided by the manufacturer. For example, installing a large-screen TV on the bedroom wall should give priority to products with larger diameter and expansion function; while building a storage system on the balcony recommend match a more waterproof model. After mastering the principles of scientific selection, even DIY enthusiasts can easily be competent for various construction tasks.

These classic examples show you how important it is to use posture correctly!

In order to let everyone more intuitively understand the huge benefits that this type of product can bring, we have compiled some representative practical examples for reference:

- reinforcement of guardrail in children's room: special lengthened screws are used to penetrate the double-layer plate directly to the keel, greatly improving the overall rigidity of the guardrail;

- comparison of kitchen cabinet bearing test: regular wood screws and professional drywall components were used to carry out hanging cabinet assembly test respectively. the results showed that the maximum load of the latter was nearly three times higher than that of the former.

- laying of decorative strips for living room background wall: replacing the traditional nail method with miniature hidden drywall fasteners, it not only meets the requirements of firmness but also beautifies the visual effect.

All of the above confirms a truth-only by mastering the correct tool selection methods and technical points can we truly tap the huge potential of each small screw.

Future Trend Outlook: Development Trend Forecast of New Fastening System in Intelligent Era

With the concept of smart home gradually rooted in the hearts of the people, once regarded as cold metal products, traditional hardware parts are ushering in a new opportunity for transformation and upgrading.

some industry observers pointed out that the future drywall connection system will integrate more sensing elements and data feedback mechanisms. for example, the built-in pressure monitoring chip can sense the force situation in real time and push early warning information through APP; another example is to develop an automatic torque adjustment control system driven by AI algorithm, so that each connection point is always in the optimal clamping state... although it is still in the frontier exploration stage at present, but its potential for development is certainly worth looking forward.

As an indispensable link in the chain of modern housing construction, "visible power" may be easier to be remembered by people, but those basic components that silently play a key role are the core of the entire living dream. Where.