In the decoration process of modern homes and office spaces, choosing the right fixing tools is essential. Especially when it comes to lightweight walls (such as gypsum board), drywall screws have become an indispensable core component. It can not only meet the basic functional requirements, but also ensure the safety and stability of long-term use.

Why drywall screws are an essential tool for modern decoration

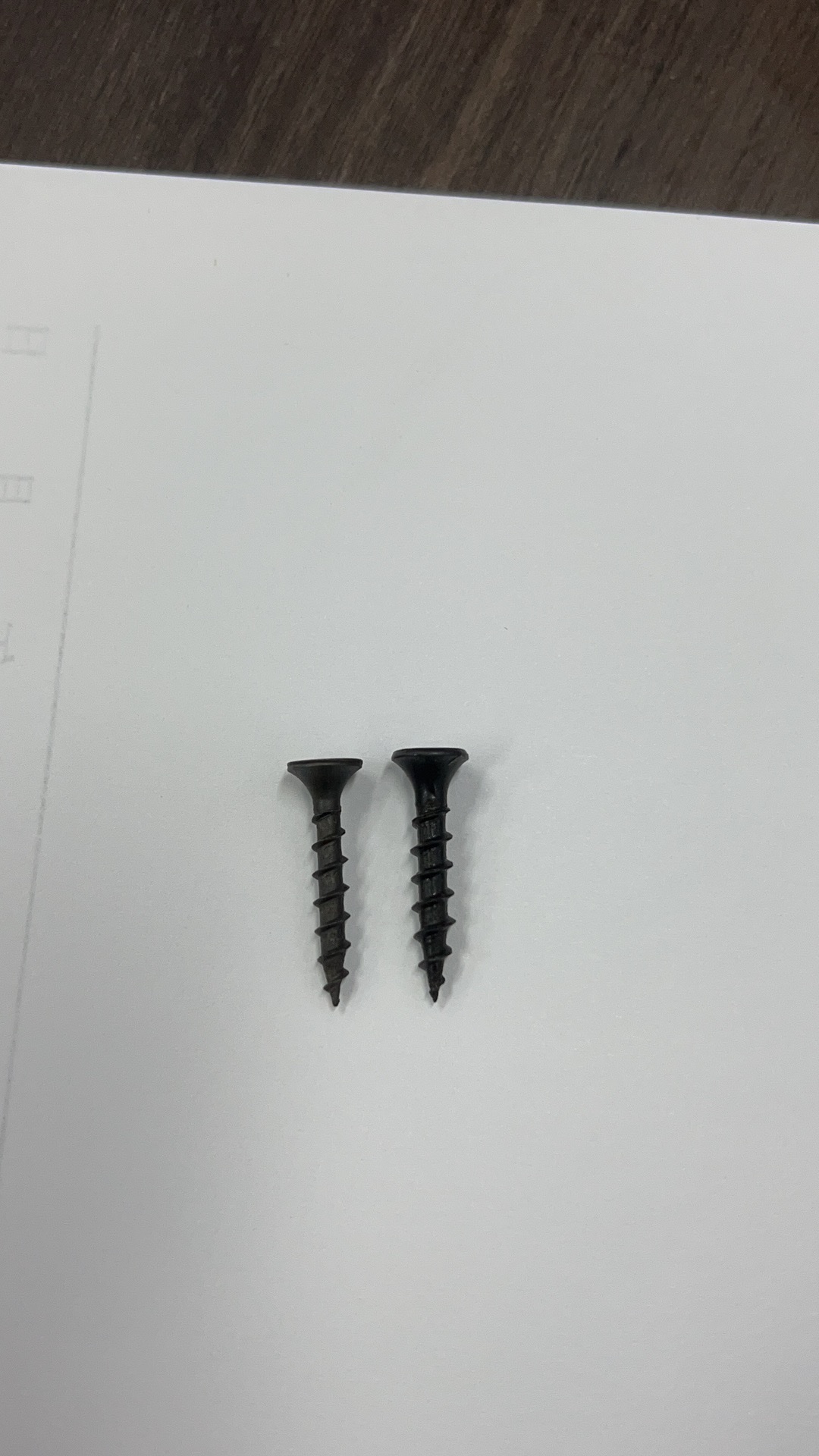

With the development of construction technology, more and more families and enterprises begin to use lightweight materials for internal structural transformation, such as gypsum board partition or ceiling construction. However, this kind of material is relatively thin and fragile, ordinary nails can not guarantee sufficient grip, easy to cause sliding or falling off phenomenon. At this time, the specially designed "drywall screw" shows an unparalleled advantage.  with special thread structure and sharp head cutting ability, it can easily penetrate the surface and be firmly embedded in the back support frame to form a tight connection state.

with special thread structure and sharp head cutting ability, it can easily penetrate the surface and be firmly embedded in the back support frame to form a tight connection state.

Learn about the key features and benefits of drywall screws

As a professional-level fastener product, the uniqueness of "drywall screws" is mainly reflected in the following aspects:

- -Strong bite force ensures reliable adhesion even on softer substrates;

- -The specially treated anti-corrosion coating extends the service life and reduces the risk of rust;

- -A variety of specifications and sizes are available for users to freely choose the most suitable model according to different project needs.

Analysis of different types of drywall screws and their applicable scenarios

There are many kinds of drywall screws on the market, which can be divided into several mainstream forms such as ordinary type, self-tapping type and extended type according to their uses. The former is mainly used for general plate splicing tasks. The latter is especially suitable for high-rise ceiling hanging heavy objects or cross-layer wall reinforcement, etc. Because of its deeper insertion depth, its bearing capacity is many times stronger than the first two.

How to choose your own high quality drywall screws

several factors should be considered clearly before purchasing. first, the length parameter must be greater than or equal to the sum of the thicknesses of the two objects to be fixed, and at least one centimeter allowance should be reserved to ensure that the grass-roots part will not be easily pulled out.

Practical teaching: the correct installation steps and skills of drywall screws

although it seems to be a simple operation, it is still necessary to pay attention to many details in order to get twice the result with half the effort. the best effect is to pre-drill a small hole with an electric screwdriver and then slowly screw in until it is completely recessed into the plane. try to keep the vertical angle as far as possible to avoid uneven stress and damage to the surrounding area due to skew. in addition, if you encounter obstacles with higher hardness, you may try to a larger number of products to solve the problem more efficiently and more safely.

Common error examples and solutions

many people often make some mistakes when trying to assemble by themselves for the first time, for example, they start blindly without measuring the accurate distance in advance. as a result, it is found that the asymmetry of hole positions seriously affects the appearance and neatness, and it is very troublesome to repair in the later period. for these problems, we give the corresponding improvement measures as follows:

always carry a tape measure to record the data information of each link before taking action after confirming it is correct; for more complex projects, it is best to seek professional guidance to complete the preliminary framework construction work and then gradually improve the rest according to the instructions until the overall completion acceptance.