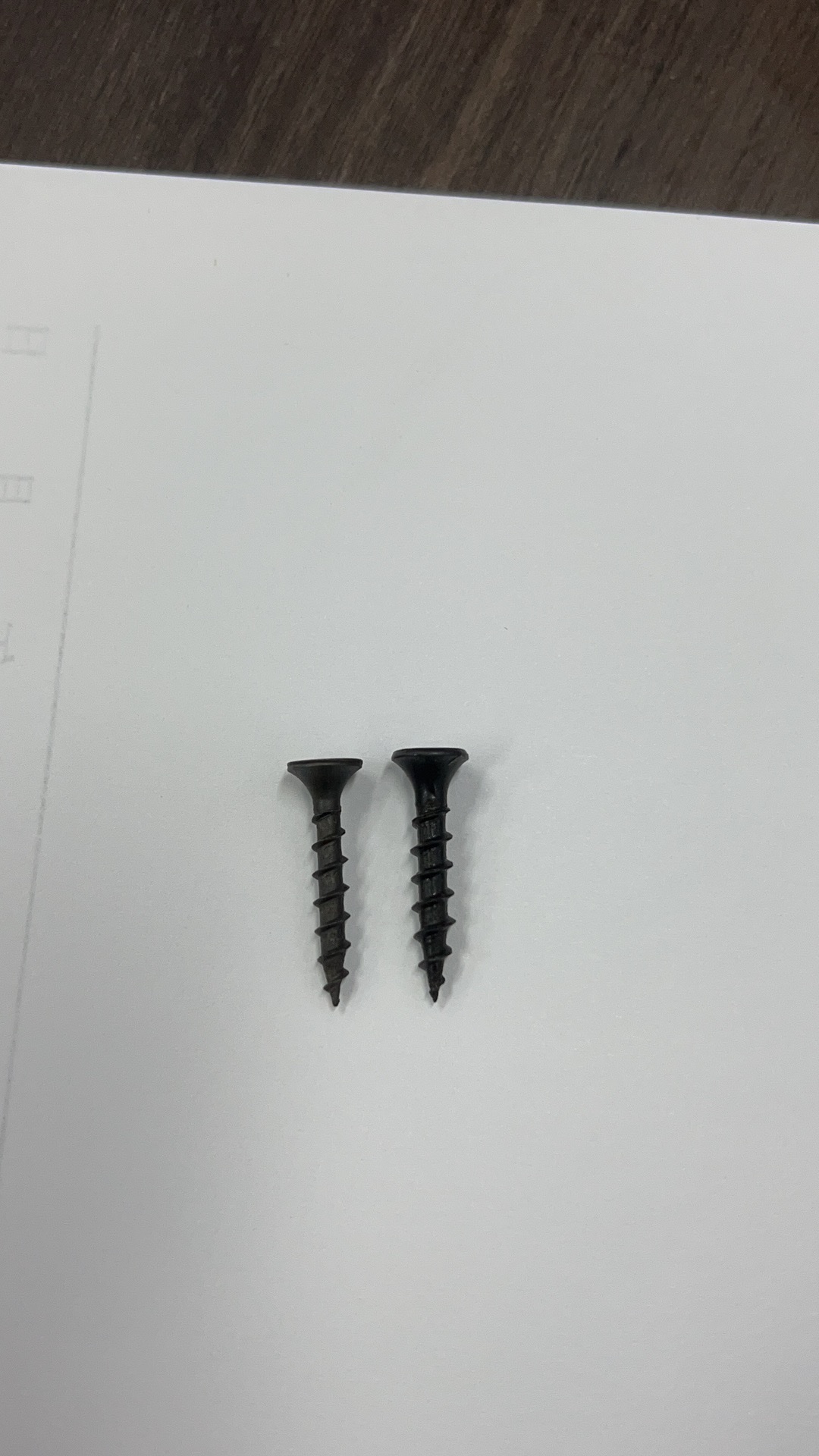

In the renovation of modern homes or commercial spaces, drywall is becoming more and more popular as an efficient and convenient decoration material. However, to achieve a beautiful and solid effect, can not do without the support of a reliable "behind the scenes hero"-drywall screw.

Drywall screws are an integral part of modern finishes because of their excellent grip and tensile strength, which allow them to securely hold gypsum board to walls or other supports. Whether it is on a flat surface or in complex terrain conditions, it can ensure that the installed wall is stable and durable.

Reveal the functional differences of different types of drywall screws and their application scenarios

There are many types of drywall screws on the market to choose from, each with unique functional characteristics to suit different application scenarios. For example, self-tapping screws are designed for rapid penetration, reducing the need for pre-drilling, while countersunk screws are designed to have a cleaner and smoother appearance because their heads are embedded in the plate.

Select drywall screws of the right length and diameter to maximize wall fixation

In order to achieve the best fixing effect, please accurately calculate the length and diameter ratio of the required screws according to actual needs. In general, thicker gypsum boards require longer and larger screws to provide sufficient support. At the same time, it is also necessary to consider the influence of factors such as the nature of the base material to make adjustments.

Material decryption: from galvanized to stainless steel, which is more suitable for your project needs?

At present, the mainstream drywall screws mainly include galvanized steel and all stainless steel. The former is cost-effective but may face rust problems, which is not ideal in humid environments; the latter, although slightly more expensive, has strong corrosion resistance and is very suitable for use in special areas such as kitchens and bathrooms.

Practical Skills Sharing: How to Quickly Judge the Quality of a Drywall Screw

When purchasing, you can initially evaluate the quality of the product by observing whether the surface treatment process is uniform and delicate. In addition, you can also try to gently twist the screw by hand to see how its hardness and elasticity perform. Really high-quality screws should feel solid and not easy to deform and break.

Guide to avoid stepping on pits-analysis of common errors and solutions

Some users often make mistakes, including blindly pursuing low prices and ignoring performance indicators or not operating in accordance with the specifications, resulting in loose connections and other issues. To solve these problems, it is recommended to do your homework in advance to understand the relevant knowledge, and strictly follow the instructions to guide the steps to perform the task.

Real Case Analysis: See how others improve the quality of the project through the correct selection of drywall screws

Mr. Zhang recently completed a living room renovation plan. under the guidance of professionals, he selected a batch of large-size extended drywall screws made of high-end stainless steel materials that are most suitable for his own environmental conditions for the construction of the entire ceiling frame. After completion, it was found that not only the overall structure was extremely robust, but also the later cleaning and maintenance became extremely simple and convenient.

To sum up, only by fully recognizing the important value of drywall screws and mastering the principles of scientific selection can we give full play to their potential to create satisfactory results!