It started with a flickering light. A homeowner proud of his weekend DIY project—a newly finished basement with smooth drywall and recessed lighting—reached up to adjust a fixture. The bulb wobbled. He tugged gently. Then came the crack, the pop, and finally, the crash as the entire housing plummeted to the floor, trailing wires like veins. The culprit? Not faulty wiring. Not poor craftsmanship. Just one small decision made at the very beginning: using the wrong drywall screw. This isn’t just about holding up a light—it’s about holding up trust in your build. Because when it comes to drywall, a tiny screw can silently determine whether your wall stands firm or fails without warning.

When Screws Meet Drywall: Unlocking the Hidden Code to Perfect Installation

The truth is, drywall isn’t just “putting up sheets.” It’s engineering disguised as carpentry. And at the heart of that engineering are screws—unsung heroes that bear invisible loads every day. Choosing the right type isn’t overkill; it’s essential. Let’s meet the crew behind the curtain.

The Drywall Screw Family Tree: Who’s Who and Where They Belong

Imagine your drywall job as a mission. Each screw plays a role, with strengths tailored to its environment.

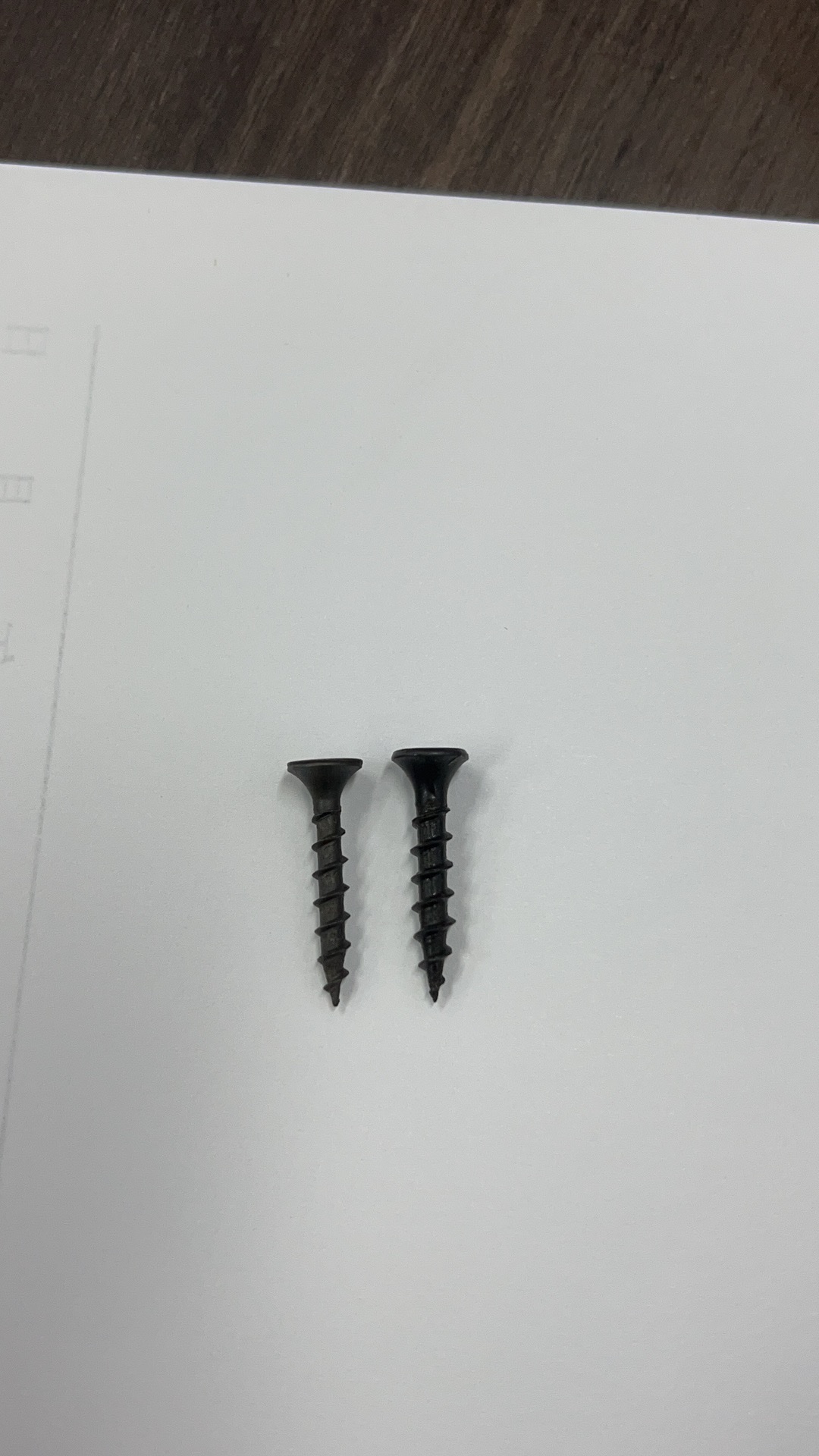

The Black Phosphate Warrior – Coarse-thread, black-coated screws don’t shout, but they grip like a vice. Ideal for standard wood-stud installations, their aggressive threading bites deep into soft lumber, delivering unmatched holding power. “I don’t need flair—just give me wood, and I’ll hold the world.”

The Silver Striker – Sleek, shiny, and built for precision, these fine-thread zinc-coated screws glide into metal studs without splitting or binding. Their corrosion-resistant armor makes them ideal for commercial builds or moisture-prone zones. “Lightning-fast entry, zero prep—metal doesn’t stand a chance.”

The Silent Penetrator – With a sharp tip and flat head designed to self-drill, this ninja eliminates pre-drilling on metal frames. It sinks flush with minimal effort, leaving no trace but strength. “No noise. No holes. Just perfection.”

The Size Puzzle: 6 or 8? 1 Inch or 1-5/8?

Picking length and gauge feels like decoding a cryptic puzzle—but it’s really a matching game. Thin 1/2-inch drywall sheets only need 1-inch screws to anchor securely into studs without piercing through the paper face. Go too long, and you risk damaging insulation or electrical lines behind the wall.

For double-layer applications—like corners or soundproof walls—step up to 1-5/8 inch screws. They bridge both layers and still grab enough wood to lock everything down. Too short? The second layer floats, creating weak spots. Too thin (like a 6)? It may strip under pressure. A robust 8 diameter handles stress better, especially near edges or high-traffic zones.

The Secret Language of Threads: What Spacing Says About Strength

Threads aren’t just grooves—they’re terrain-specific tools. Coarse threads act like cleats in soil, gripping soft wood fibers with maximum friction. That’s why they dominate residential builds with wooden framing.

Fine threads, meanwhile, are precision instruments. On steel studs, they engage more gradually, reducing the risk of thread stripping and ensuring consistent torque. Think of it like hiking boots: wide lugs for mud, tight treads for rock. Match the thread to the terrain.

Coatings: More Than Just a Pretty Finish

That dark phosphate coat isn’t just for looks—it’s a silent guardian against oxidation and vibration loosening. Affordable and effective, it’s the go-to for interior spaces.

Zinc-plated screws shine where humidity lurks—bathrooms, basements, utility rooms. Their silvery shield resists rust even when condensation forms overnight.

And then there are color-coded variants—blue, yellow, red tips—that let crews instantly identify screw types mid-project. One glance, and everyone knows which goes where. Efficiency meets accuracy.

The Ritual of Installation: Precision in Every Turn

Hold your drill at a slight angle—just 5 to 10 degrees off perpendicular. This reduces lateral stress on the drywall paper, preventing tears around the head. Feel for resistance. Listen closely. When the screw seats perfectly, you’ll hear a soft “kak-kad”—a subtle click signaling full embedment.

Seasoned pros call it “training your ears.” Too loud? You’re overdriving. Too quiet? It hasn’t reached the stud. Practice on scrap until the rhythm feels natural.

Beyond Drywall: Hidden Talents of These Tiny Titans

These screws aren’t one-trick ponies. Use coated versions to secure rigid foam insulation along rim joists. Temporarily assemble light-duty wooden frames during layout phases. Even attach lightweight outdoor soffits or covered porch panels—if the coating is rated for exterior use.

When You Hear the Crack: Warning Signs of Silent Failure

Months after installation, watch for telltale signs: raised bumps along screw lines, spiderweb cracks radiating from heads, or hollow sounds when tapping the wall. These mean either the screw sank too deep (breaking the paper backing) or failed to reach the stud.

Fix minor issues by countersinking nearby replacements and patching. Prevent future problems with proper depth stops on your drill and consistent stud-finding routines.

The Foundation of Flat: Begin with the Right Screw

Every flawless wall begins not with paint or tape, but with a choice. Hundreds of screws lie buried beneath the surface, unseen but unyielding. They don’t ask for credit—they simply hold. So next time you pick up a drywall sheet, remember: greatness isn’t measured in square footage. It’s hidden in the hundred tiny decisions that keep everything standing true. Start with the right screw. The rest will follow.