Drywall Screw Guide: Types, Uses & How to Choose the Right One

Imagine this: a beautifully finished bathroom wall, smooth and pristine—until a hairline crack begins to spread near the ceiling. Behind that flaw lies a hidden culprit: a corroded drywall screw, weakened by humidity, slowly pulling away from its hold. It’s not a structural collapse, but it might as well be—one tiny fastener, overlooked during installation, now undermining months of craftsmanship.

This isn’t just about aesthetics; it’s about integrity. Whether you're renovating a century-old home or constructing a sleek office space, the right drywall screw does far more than anchor sheets to studs—it silently ensures durability, safety, and long-term performance. Let’s dive into the world behind the wall, where engineering meets environment, and discover how choosing wisely can elevate your entire build.

From Gypsum Board to Flawless Finish: The Hidden Science Behind Every Screw

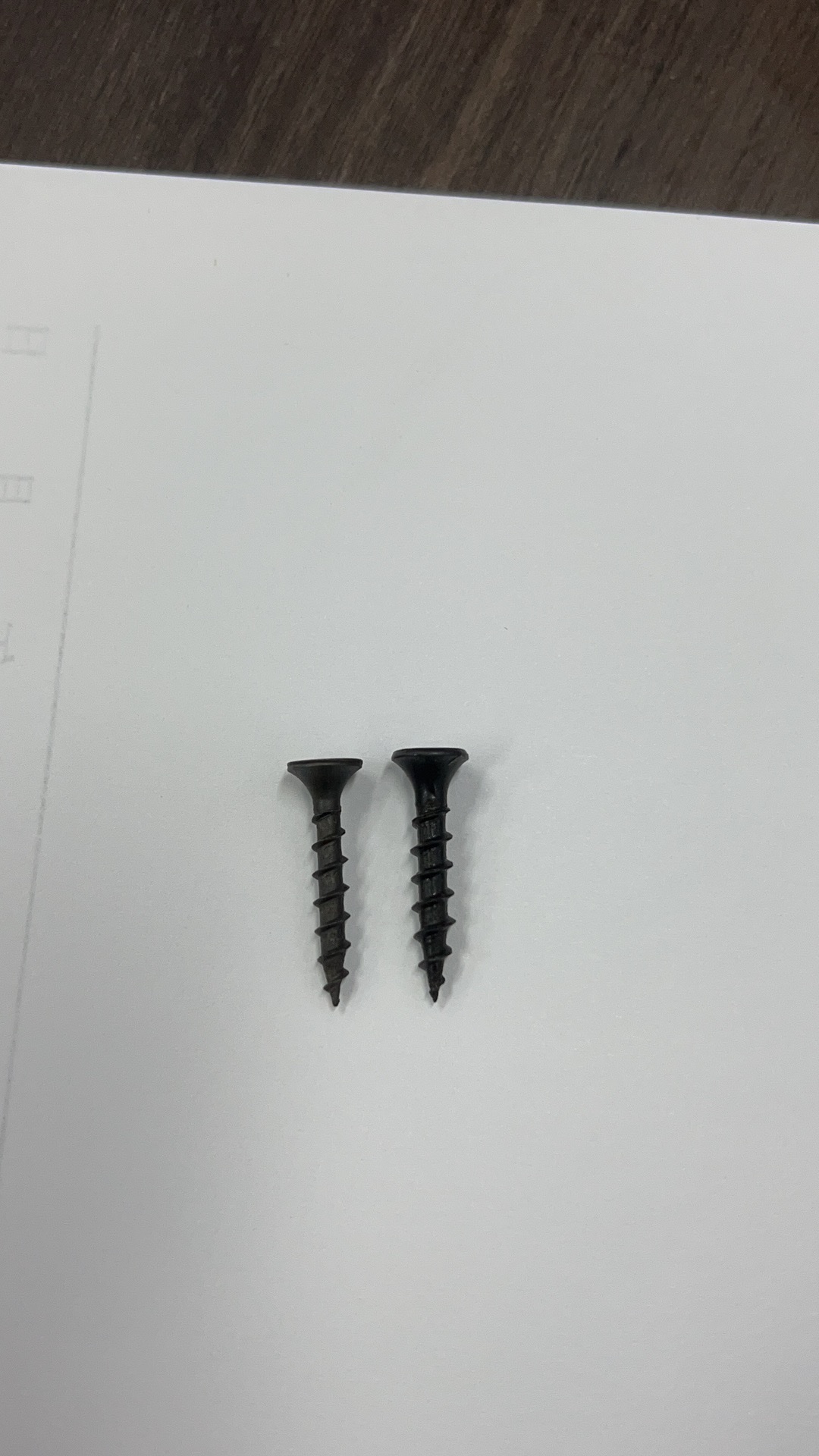

The head shape of a drywall screw may seem trivial, but it plays a crucial role in surface finish. Hex washer heads provide superior torque transfer and are ideal for metal framing, especially in commercial settings where speed and reliability matter. On the other hand, bugle (flat-countersunk) heads are engineered to sink cleanly into drywall without tearing the paper face—a must for seamless taping and mudding.

Material composition is equally critical. Standard phosphate-coated screws resist mild indoor conditions, but when moisture enters the equation—like in kitchens or bathrooms—zinc-plated or even SS316 stainless steel becomes essential. These corrosion-resistant variants withstand condensation and temperature swings, preventing rust stains and joint failure over time.

Then comes the tip design. Self-drilling (or drill-tip) screws slice through light-gauge steel with minimal effort, eliminating pre-drilling and reducing labor costs. For wood framing, sharp self-tapping points offer clean penetration while minimizing splitting. Pair these with the correct thread pattern—fine threads for metal, coarse for wood—and you’ve got a fastener that bites deep and holds firm.

The Silent Strength Within: How Screws Bear the Unseen Load

Beneath the paint and plaster, drywall screws endure constant stress—thermal expansion, vibration, even minor seismic shifts. High-quality screws maintain tensile strength under prolonged load, resisting pull-out forces that cheaper alternatives succumb to. Over time, inferior screws creep outward, creating dimples on the surface or worse—loose panels that rattle with footfall.

In contrast, premium-grade screws feature precision-rolled threads and heat-treated cores, delivering consistent performance across thousands of installations. They don’t just attach; they integrate, forming a unified system between board and frame that resists deformation and enhances overall wall rigidity.

Match the Screw to the Space: Smart Selection for Real-World Projects

No two jobs are alike, and neither should your fasteners be. In high-moisture areas like showers or laundry rooms, opt for fully stainless steel screws rated SS316—they resist chloride exposure and won’t degrade even in steamy environments. When working with lightweight steel studs, fine-threaded self-drilling models prevent stripping and ensure secure engagement.

Renovations often involve patching old drywall. Here, low-profile or “filler head” screws minimize protrusion, making them easier to conceal with joint compound. For suspended ceiling grids in offices or retail spaces, hex-head screws driven with impact drivers enable rapid, fatigue-free installation across vast square footage.

Pro Techniques: Secrets from Master Installers

Seasoned contractors know that proper installation is as important as the screw itself. Driving too deeply ruptures the drywall paper, compromising adhesion and inviting cracks. Too shallow, and the screw head remains proud, causing visible bumps. The sweet spot? Slightly below the surface, flush with the cardboard layer but not breaking it.

Spacing also follows logic: a standard 12-inch interval along edges and field studs balances support with material flexibility. Edge distance should be at least 3/8 inch to avoid crumbling corners. And remember—temperature matters. Cold weather contracts metal; hot conditions expand it. Anticipate seasonal movement by adjusting tension accordingly, especially in unconditioned spaces.

Building Greener, One Screw at a Time

Sustainability isn't limited to insulation or solar panels. Modern drywall screws contribute by using recyclable carbon steel and energy-efficient coating processes. Longer service life means fewer replacements, less waste, and reduced maintenance emissions. Some manufacturers now offer eco-conscious lines with non-toxic finishes and traceable sourcing—small steps toward lower-carbon construction.

Avoiding Costly Mistakes: Spotting Substandard Screws

Cheap imitations often reveal themselves quickly. Look for uneven plating, rough threads, or inconsistent tapering. A magnet test helps identify stainless steel (most grades are non-magnetic); if a "stainless" screw sticks strongly, it’s likely inferior 400-series steel. Drop a sample in water overnight—rust spots within hours signal poor protection.

Vague packaging lacking ASTM standards or material specs is another red flag. Trust only brands that specify grade, coating type, and application use clearly.

The Future of Fastening: Where Technology Meets Precision

Tomorrow’s drywall screws go beyond holding power. Innovations include depth-limiting collars for uniform drive depth, polymer-coated threads for improved grip, and smart packaging synced with inventory apps. As robotic installers enter construction sites, standardized, high-tolerance screws will become the backbone of automated drywall assembly.

Every Screw Tells a Story

Beneath layers of texture and tone, invisible yet indispensable, drywall screws form the quiet foundation of our living spaces. They’re not just hardware—they’re commitment to quality, foresight in design, and respect for the craft. Next time you run your hand across a perfect wall, remember: greatness isn’t always seen. Sometimes, it’s held together by something small, strong, and perfectly chosen.