When it comes to construction and home improvement, small details often make the biggest difference. One such detail that’s frequently overlooked is the humble drywall screw. While it may seem like a minor component in the grand scheme of a building project, the right drywall screw can be the difference between a solid, long-lasting wall and one that cracks under pressure. Whether you're a DIY enthusiast or a professional builder, understanding the nuances of drywall screws can significantly impact the quality and durability of your work.

Why Drywall Screws Matter More Than You Think

At first glance, drywall screws may appear to be just another fastener, but they play a crucial role in ensuring structural integrity and longevity in drywall installations. These tiny yet powerful fasteners serve as the invisible framework that holds your walls and ceilings together. Choosing the right type of screw not only ensures a secure fit but also prevents future issues like sagging drywall, cracking surfaces, or even structural failure in extreme cases.

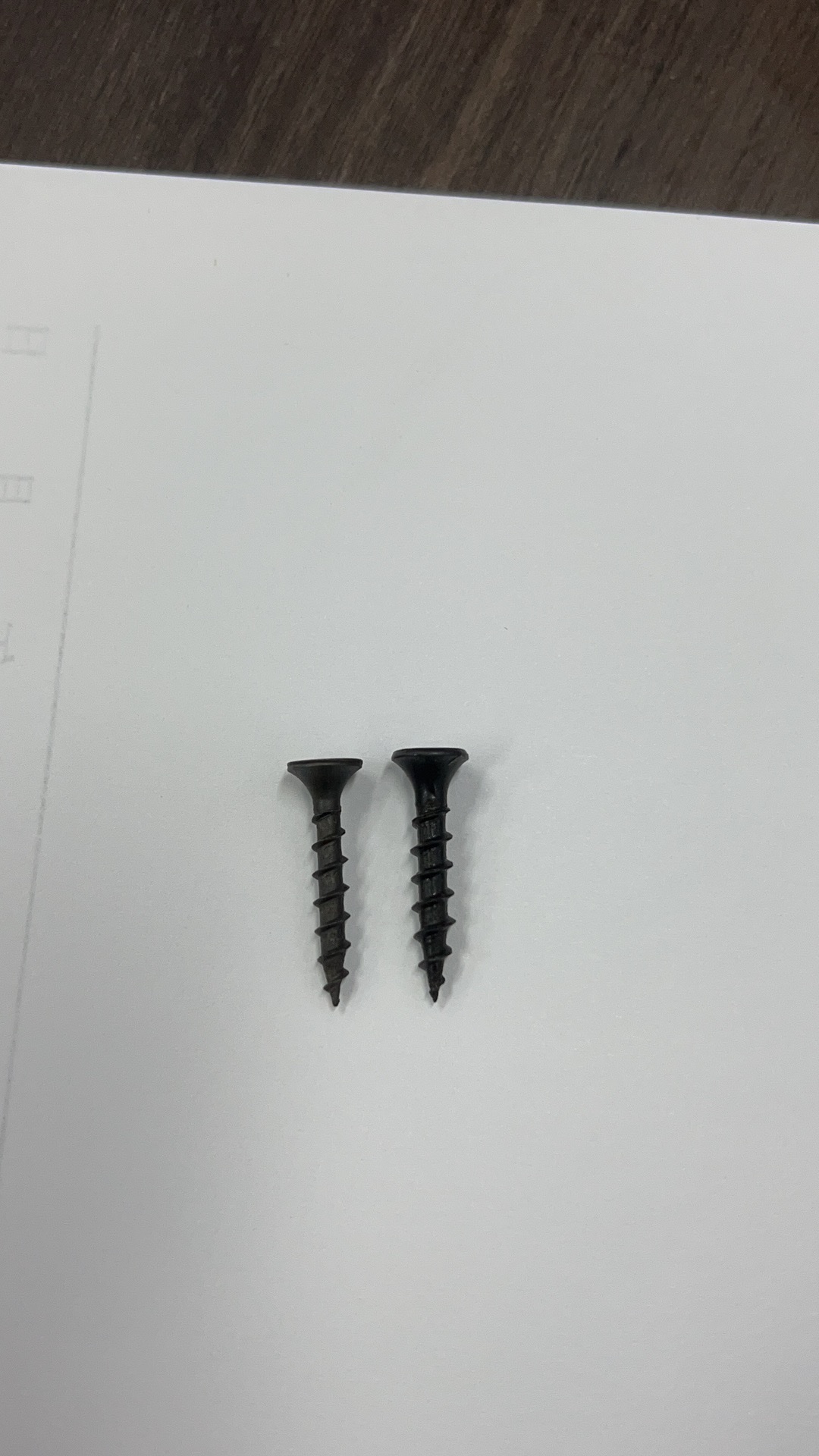

Using the wrong type of screw—such as wood screws or deck screws—can lead to poor performance. Drywall screws are specifically engineered with features like sharp points and aggressive threading to bite into the gypsum core and the supporting structure behind it. This ensures that your drywall remains securely in place, resisting movement and maintaining a clean, smooth surface over time.

The Many Faces of Drywall Screws: Types and Their Uses

Not all drywall screws are created equal. The market offers a variety of options designed to suit different applications and environments. Understanding these differences can help you make informed decisions that improve the outcome of your project.

Fine-thread vs. Coarse-thread: Fine-thread screws are best suited for metal studs, where their finer threads provide better grip and reduce the risk of stripping. Coarse-thread screws, on the other hand, are ideal for wood studs, offering a more aggressive bite that ensures secure fastening in softer materials.

Coating Matters: From zinc-plated to black phosphate, the coating on a drywall screw affects both its durability and performance. Zinc-coated screws are resistant to corrosion, making them suitable for environments with higher humidity. Black phosphate screws, while not as corrosion-resistant, offer excellent grip and are often preferred for interior drywall installations.

Head Styles: The head of the screw determines how it seats into the drywall. Flathead screws are designed to sink just below the surface without tearing the paper, while bugle-head screws have a rounded design that allows for a flush fit without damaging the drywall surface. Hex-head screws are commonly used in commercial applications and are often paired with a screw gun for faster installation.

Choosing the Right Drywall Screw for Your Project

Selecting the appropriate drywall screw involves more than just picking a length and thickness. Several factors come into play, including the type of material you're fastening into, the thickness of the drywall itself, and the environmental conditions of the installation area.

Material Compatibility: If you're attaching drywall to wood studs, coarse-thread screws are typically the best choice. For metal framing, fine-thread screws offer superior holding power without damaging the stud. In concrete or masonry applications, specialized self-tapping screws or anchors may be necessary.

Drywall Thickness: Thicker drywall requires longer screws to ensure proper anchoring. A general rule of thumb is that the screw should penetrate at least 3/4 inch into the supporting structure. For standard 1/2-inch drywall installed on wood, 1-1/4 inch screws are commonly used.

Environmental Considerations: In areas prone to moisture, such as bathrooms or basements, selecting screws with anti-corrosive coatings can prevent premature failure. In high-vibration environments like garages or near HVAC units, using vibration-resistant screws or applying a small dab of construction adhesive can help maintain a secure hold.

Installation Tips for a Professional Finish

Even the best drywall screw won’t perform well if it's not installed correctly. The way you drive the screw into the drywall can affect both the structural integrity and the aesthetic finish of your walls.

Angle and Depth: Screws should be driven straight into the drywall at a 90-degree angle to avoid cracking the surface. They should be sunk just below the surface of the paper without tearing it. Over-driving can create dimples that are difficult to cover with joint compound.

Spacing: A consistent screw pattern ensures even support across the drywall panel. Typically, screws should be spaced about 12 to 16 inches apart along the edges and 16 inches in the field. This spacing helps prevent sagging and reduces the likelihood of nail pops or cracks forming later.

Tool Use: Using a screw gun with adjustable torque settings can help prevent over-driving. If you're using a drill, be sure to use a clutch setting that stops the bit once the screw is seated properly. Manual screwdrivers are not recommended for large projects, as they can be time-consuming and lead to uneven results.

Unexpected Uses of Drywall Screws

While drywall screws are primarily used for installing drywall, their versatility extends far beyond that. Many homeowners and builders have found creative ways to use them for a variety of applications around the house.

For instance, drywall screws are ideal for mounting lightweight shelves or hanging picture frames. Their ability to grip securely into the drywall makes them a reliable option for securing small to medium-sized items. In commercial settings, they can be used to mount signage, lighting fixtures, or even temporary partitions in event spaces.

Some DIYers even use drywall screws for assembling lightweight furniture or creating wall-mounted storage solutions. With the right anchors, they can support heavier items like floating shelves or flat-screen TVs—though for heavier loads, it's always best to anchor into the stud behind the drywall.

Common Questions About Drywall Screws

Even experienced builders sometimes have questions about drywall screws. Here are a few common ones that might help clarify things:

- Do drywall screws rust? While most drywall screws are coated to resist corrosion, they can still rust over time, especially in humid environments. Choosing screws with zinc or composite coatings can help extend their lifespan.

- Can you reuse drywall screws? Reusing drywall screws is generally not recommended, as the threads may become worn or stripped, reducing their holding power.

- Why do some screws sink below the surface? Over-driving or using screws that are too long can cause them to sink too deeply. Always use the correct length and apply even pressure when driving the screw.

- Can wood screws be used for drywall? While wood screws can be used in a pinch, they lack the sharp point and aggressive threading of drywall screws, making them less effective for this specific application.

The Future of Drywall Screws: Sustainability and Innovation

As the construction industry moves toward more sustainable practices, the world of fasteners is evolving as well. Manufacturers are exploring eco-friendly coatings and recyclable materials to reduce environmental impact. Some companies are even experimenting with smart screws embedded with sensors that can monitor structural integrity in real time—a feature that could revolutionize building maintenance in the future.

In addition, industry standards for drywall screws are continuously improving, with new specifications ensuring better performance and safety. Whether it's through enhanced corrosion resistance, improved torque control, or innovative design features, the next generation of drywall screws promises to be more efficient, durable, and environmentally friendly than ever before.

Final Thoughts

Whether you're building a new home or simply hanging a picture frame, the right drywall screw can make all the difference. By understanding the different types, choosing the appropriate size and coating, and mastering the correct installation techniques, you can ensure that your drywall remains secure and looking great for years to come.

So next time you reach for that box of screws, take a moment to consider the role they play in your project. With the right knowledge and tools, even the smallest components can have a big impact on the quality of your work.