Understand the basic functions and structural characteristics of drywall screws

As a fastening element frequently used in the field of modern home improvement, drywall screws have become an indispensable key component in various wall installation projects due to their excellent connection strength and good load-bearing performance.

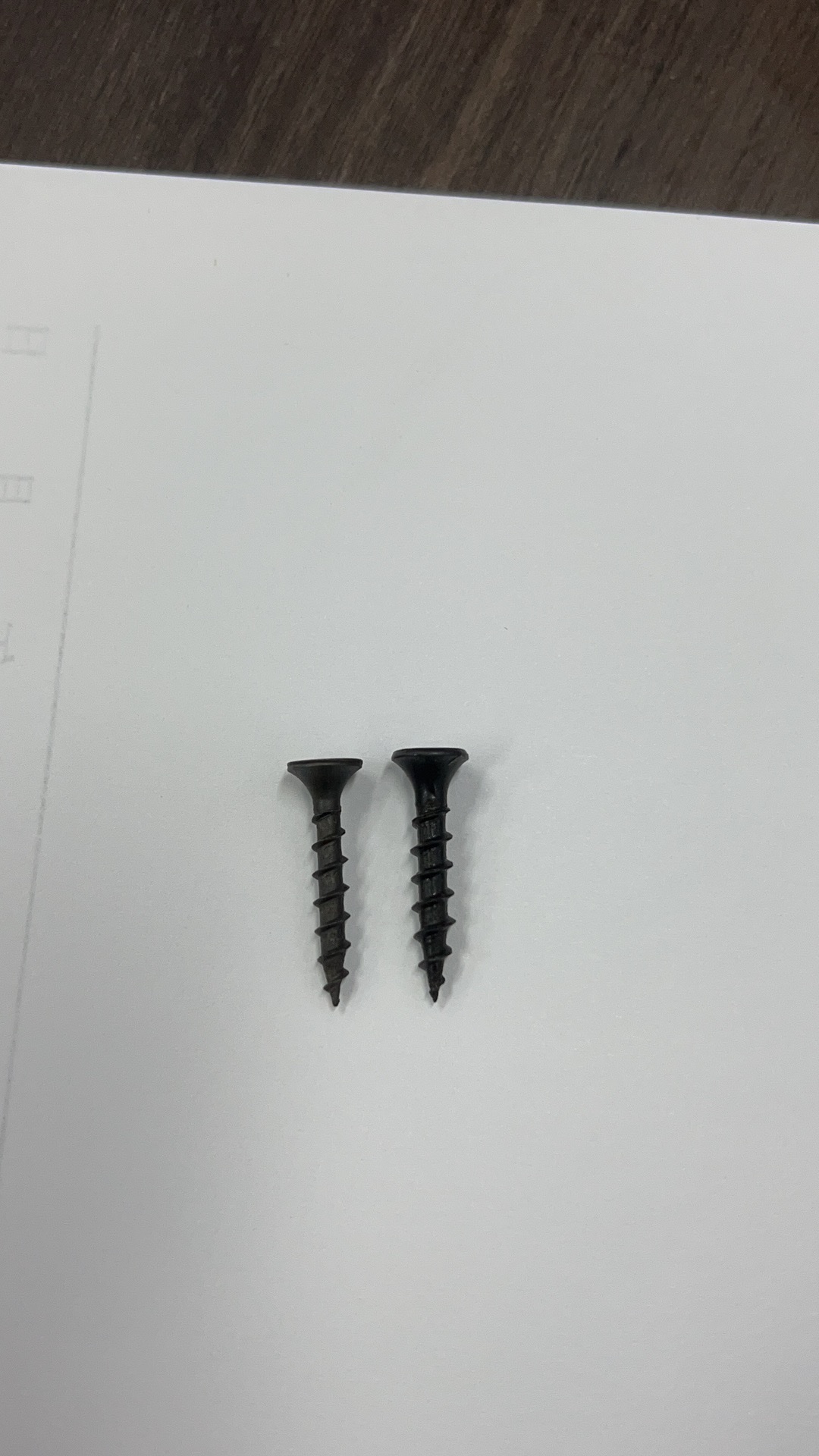

The unique thread structure enables it to be tightly embedded in the gypsum board and firmly attached to the wall foundation layer, greatly reducing the safety hazard caused by vibration.

Compared with traditional expansion anchors, drywall screws show higher adaptability and convenience, and are especially suitable for connecting hollow walls and thinner materials.

The mainstream high quality drywall screws on the market are mostly refined from high-carbon steel or stainless steel, supplemented by anti-oxidation coating treatment process, which greatly delays the aging process and ensures that they are still stable after years of use.

Diversified uses to match various indoor installation requirements

from hanging decorative paintings, assembling bookshelves to lamp brackets and even curtain guide devices, as long as non-structural mounting tasks are involved, drywall screws are capable of fulfilling their mission.

whether it is a home renovation project or an enterprise office upgrade, proper selection of products of corresponding specifications will significantly improve construction efficiency, reduce labor input and retain a clean and beautiful visual experience.

Low-density walls, such as lightweight bricks, are gaining popularity as new materials continue to emerge in the construction industry, underscoring the huge advantage of drywall screws that can be quickly positioned and fixed without pre-drilling.

Grasp the key parameters and select the right model accurately

the current market supply types are complicated, the regular length span is between one inch and three inches, consumers should make a rational choice according to the expected load size and the thickness of the material involved, in order to obtain the most ideal stress distribution state.

the strength of self-tapping ability directly affects the smoothness of construction operations. therefore, it is recommended to give priority to commodities with conical front end and deep groove design, which is helpful to cut into complex texture surfaces faster and more stably without causing caton sliding teeth.

a few high-end versions are equipped with customized plastic expansion tube components, which still maintain sufficient pull-out resistance index under loose substrate conditions, thus significantly enhancing the safety redundancy during the operation of the overall system.

Professional Skills Help Improve Installation Success Rate

although this type of product features no pre-drilling, in order to achieve higher precision assembly requirements, it is still one of the necessary preliminary preparations to make accurate positioning marks in advance and appropriately adjust the speed of the electric drill.

using a suitable electric screwdriver to operate with the standard batch head can not only greatly avoid the probability of sliding buckle problems, but also help to control the consistent insertion depth level to create a neat and pleasing final look.

even after the completion of the project, it should not be taken lightly. it is also very important to check whether there are signs of deviation in each riveting part at the right time and immediately start to correct it, especially in geologically active areas or spaces that are often subjected to strong shaking interference, such as children's bedrooms, etc., and pay special attention to the implementation of maintenance measures.