New darling of indispensable basic building materials for modern architecture

In recent years, with the continuous improvement of people's pursuit of the quality of the living environment, home improvement materials are also constantly evolving and upgrading.

Driven by this trend, a revolutionary connection component designed for lightweight partition walls has emerged and gradually won the favor of architects and decoration masters.

Compared with the traditional expansion bolt or wooden wedge fixing method, it is not only faster and more convenient for construction, but also has a significant improvement in long-term reliability. It has become one of the standard options for many new or refurbished projects.

Extraordinary load-bearing capacity and operation-friendly degree of precision construction

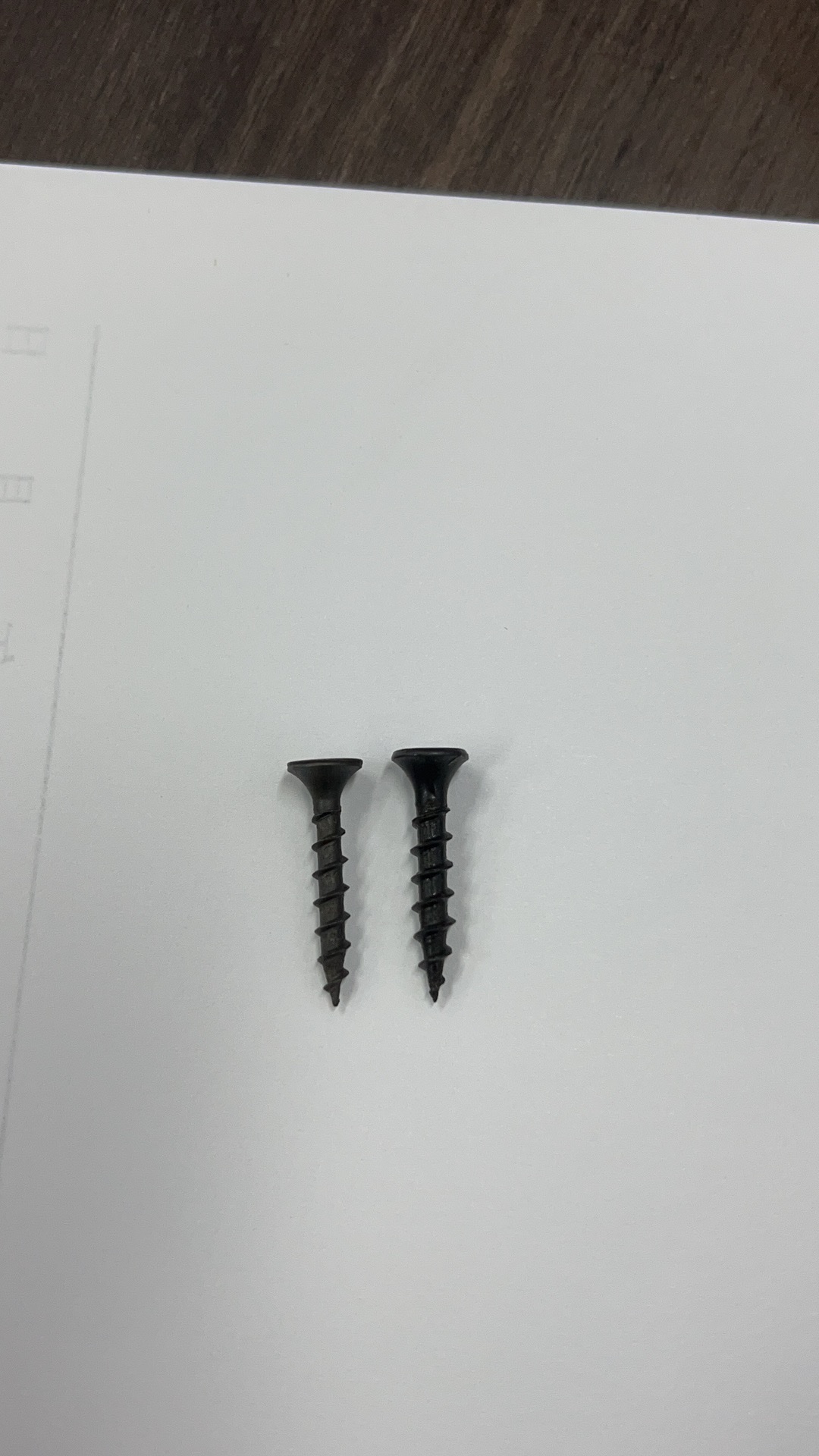

the biggest highlight which is different from ordinary self-tapping nails lies in its scientific and rigorous overall layout scheme-from the spiral angle to the tip shape, it is accurately calculated to match the demand characteristics of plates with different thicknesses.

The unique tapered guide head makes the entire embedding process extremely smooth, almost without any destructive pressure waves, thus avoiding the risk of damage to the surrounding structure.

In addition, the jagged design elements located under the head further strengthen the bite between the interfaces, making the final bond more unbreakable than ever before.

Widely adapted to installation requirements in a variety of complex environments

whether we are facing the private and warm family home renovation project or the renovation site of large public facilities such as shopping malls and hotels, these products can flexibly cope with various practical challenges.

whether it is used to mount heavy art picture frames, hanging cabinet kitchen utensils or even ventilation pipeline systems and other high-load objects, you only need to choose the right size model to be able to firmly fix every corner without fail.

More importantly, they are made of corrosion-resistant alloy raw materials and treated with a special electroplating coating, which is also easy for those workplaces that are exposed to moisture or dust all the year round.

Saving Time and Cost Helps Accelerate Project Progress

Say goodbye to the old method of drilling a hole with an electric drill and then inserting a plastic sleeve before screwing in the screw!

now you only need an electric screwdriver and the correct type of special quick-fit drywall nail to complete the whole process at one go ~ compared with the traditional method, it can speed up at least 1/3 or more!

and thanks to the worldwide implementation of the quality management system certification system under the protection of each batch of goods will be strictly in accordance with the established parameters of the inspection control to ensure consistency to avoid the trouble of repeated adjustment.

Green concept throughout the entire life cycle management

from the initial raw material procurement stage began to emphasize the guiding ideology of sustainable development and resolutely eliminate all factors that may pose a threat to human health, such as the existence of lead, cadmium, hexavalent chromium and other toxic metal residues, the possibility of completely eliminating potential safety hazards.

The feature of multiple disassembly and assembly is very suitable for short-term exhibition booth settings and modular office unit transportation arrangements, especially in emergency situations, rapid response deployment is particularly valuable.

when the service period expires and decommissioned, because the material is relatively simple and easy to separate and recycle, it is very convenient to enter the recycling industry chain to minimize waste emissions, actively respond to the national strategic call on low-carbon, energy-saving and green manufacturing, and fulfill due corporate citizenship obligations.