High-strength galvanized material, suitable for fastening connection of various wall structures

In the field of construction engineering and interior decoration, a seemingly insignificant but vital link often determines the safety and stability of the overall structure. This is exactly what we're going to delve into today-drywall screws. They may not be as conspicuous as reinforced concrete, but they play an irreplaceable role in the construction and decoration of lightweight walls, and are one of the basic building materials trusted by professional technicians and owners.

Understanding the unique charm of drywall screws from the foundation

Drywall screws are not as simple as ordinary self-tapping nails. They are specially designed for gypsum board, cement-based composite board and other non-metallic wall materials, with higher bite force and anti-slip function. Compared with traditional wood screws or general-purpose steel nails, these products usually use fine threads with tapered tips, making them easier to insert into walls and reducing the risk of breakage.

In addition, the surface is plated to enhance corrosion resistance and maintain long-term reliability in environments with large humidity changes. Because of these qualities, drywall screws are gradually replacing old expansion anchors as the mainstream option in modern residential renovation and new construction projects.

All-round application-strong compatibility covering multiple scenarios

Whether you're a home DIY enthusiast renovating your kitchen ceiling or a member of a team of project managers overseeing the renovation of a large office building, you'll find this hardware offers unprecedented convenience. Taking the most common gypsum board installation as an example, the use of special drywall screws can not only speed up the construction progress, but also ensure that the joints between the boards are flat and free of warping.

In more challenging commercial sites, engineers are often seen using specific models (e. g., coarse teeth) to penetrate thick insulation foam sandwich walls, or even to reinforce areas around embedded pipeline pathways. Even in the face of high vibration frequency or temperature fluctuations in the work environment is also fearless, showing excellent durability performance.

Selection Guide: Select the high quality Drywall Screws for Your Project

the dazzling array of brands on the market is dizzying, but truly high-quality drywall screws must meet several key indicators: first, the hardness of steel is reasonable, and if it is too soft, it is easy to bend and slip; Secondly, the coating is uniform and dense to effectively prevent water vapor erosion. Finally, the head drive notch has extremely high precision and is convenient for electric tools to apply force accurately.

if you plan to use this batch of goods in wet areas such as bathrooms and toilets, please give priority to products made of stainless steel version or double-sided hot-dip zinc process. if the focus is on the daily maintenance and replacement is simple and quick, the cross groove with guide rib type is particularly practical and convenient.

The economic ledger behind the efficiency upgrade

According to statistics, the use of high-performance drywall screws for tasks of the same size can save an average of about 1/3 of labor time expenditure, which means that not only can the delivery time be shortened, but also the overall labor expenditure pressure can be reduced. The person in charge of the renovation project of a chain hotel revealed: "Since the new high-speed screw-in drywall screws were used, each worker can complete at least two more standard ceiling assembly operations in two more rooms every day than before."

It is also worth noting that when the number of orders reaches a certain level, manufacturers often give considerable discounts and free logistics and distribution services, which is undoubtedly an attractive cost-cutting tool for small and medium-sized contractors.

Future Trends and Prospects

along with the country to vigorously promote the prefabricated housing construction model, for the supporting hardware components put forward higher requirements. Future drywall screws should not only continue to strengthen their own strength and life limit, but also need to move towards the direction of intelligence, such as built-in sensors to monitor stress distribution and other functional modules to explore the possibility of integration.

At the same time, the "Green Building Evaluation Standard" is becoming more and more stringent, prompting manufacturers to continuously improve the production process to minimize the environmental pollution caused by the pickling and phosphating process, and to turn to a cleaner and more environmentally friendly nano-ceramic coating technology route has begun to take shape. Whoever can take the lead in grasping this round of change is expected to occupy a larger market share in the next few years.

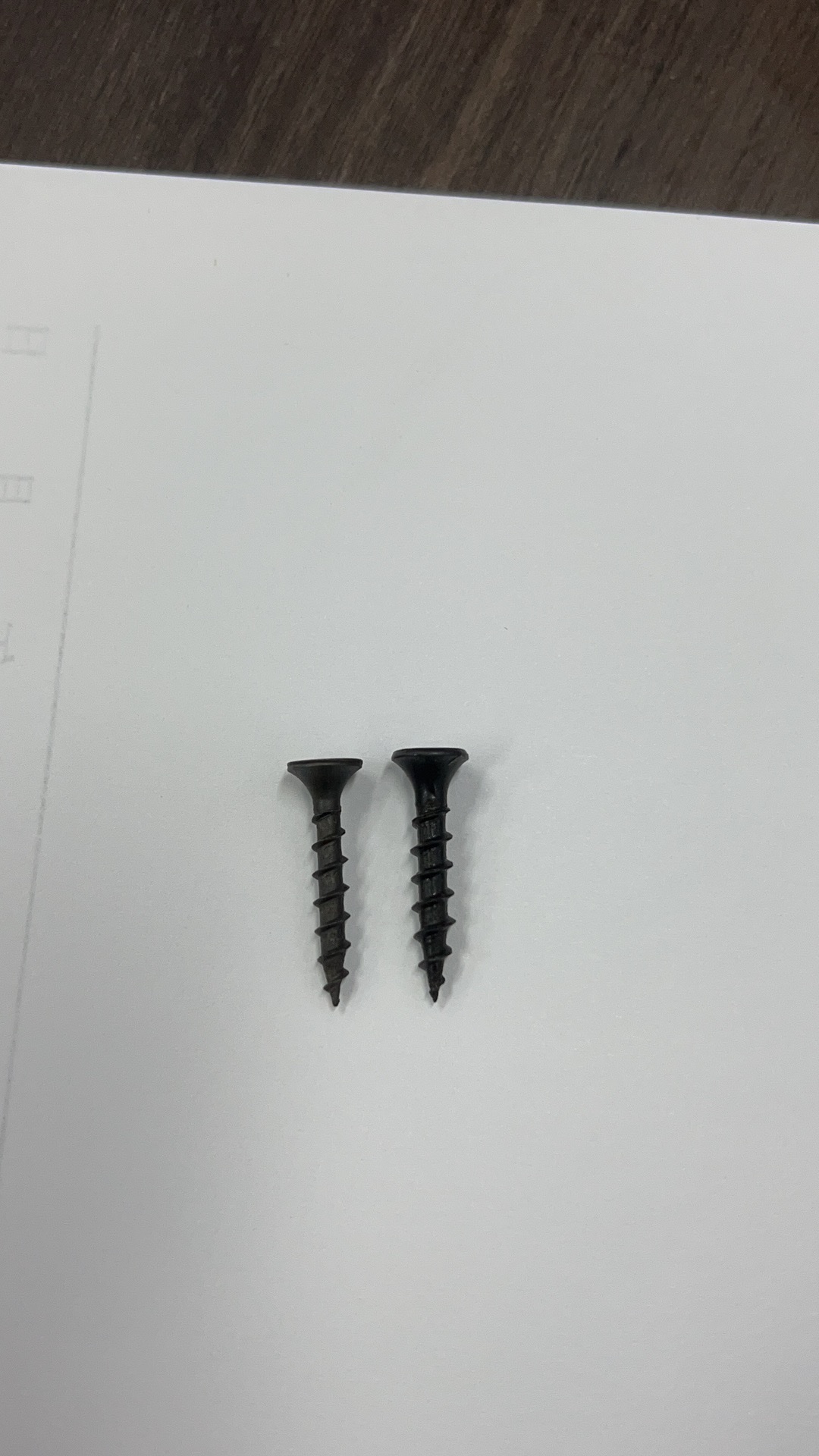

The picture on the left shows the state of screwing into the wall during the actual construction stage/the right side presents various length and diameter choices for customers to order on demand