In the process of home improvement, the stability and construction efficiency of the wall fixing often determine the quality of the overall project. When it comes to wall anchoring tools, we have to mention the professional players who have been favored in recent years- drywall screws . Whether you are a professional decorator or a DIY enthusiast, this drywall screw can become your indispensable right-hand man.

Uncover the mystery of drywall screws: why is it the heart of decorators?

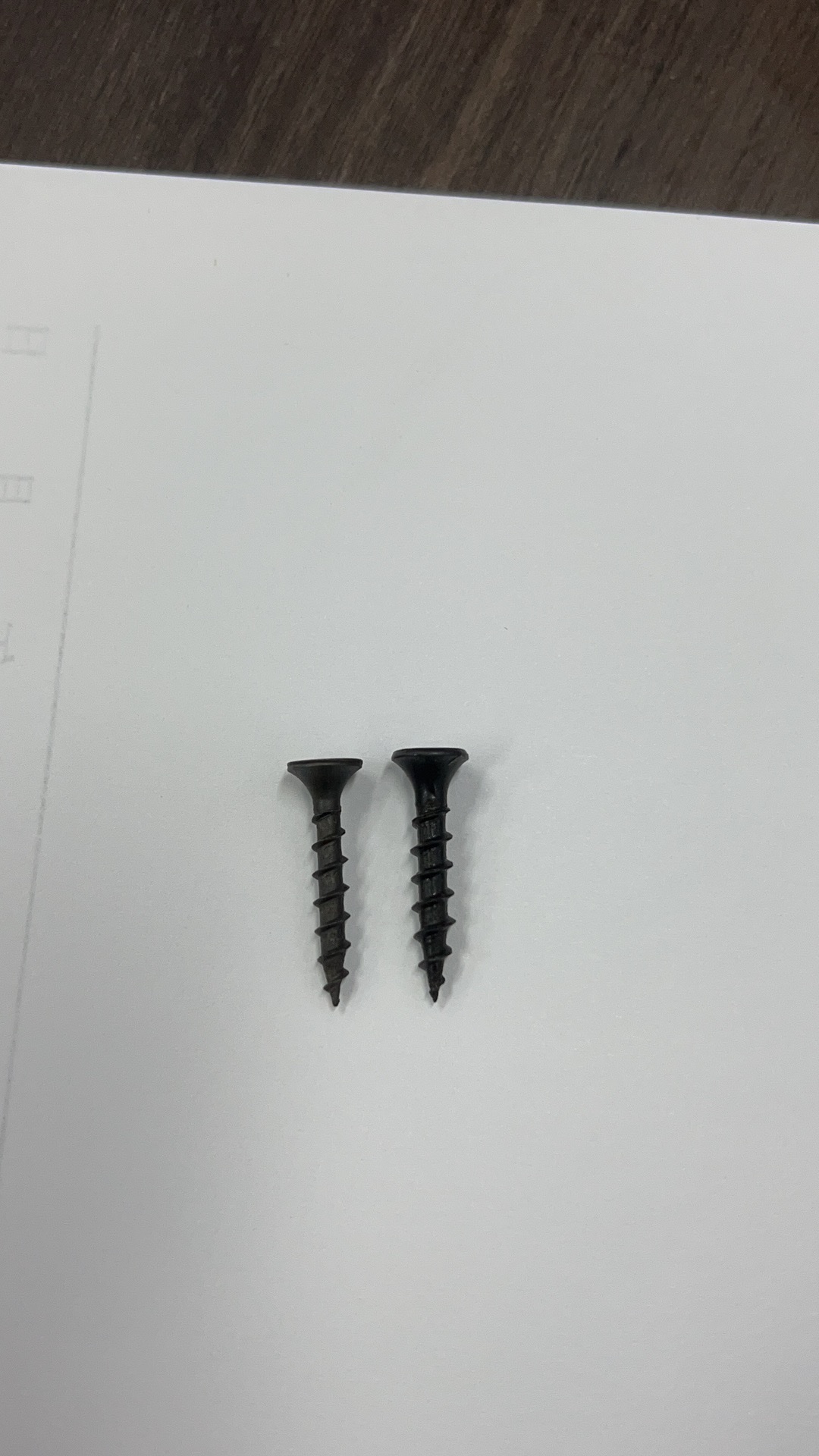

Different from ordinary screws, drywall screws are specially designed for lightweight walls such as gypsum board and cement hollow bricks. It has a unique pitch design and tip structure, can be quickly embedded in the base material without pre-drilling, firmly grasp the plate without cracking. This balance of strength and convenience features, so that it quickly captured the hearts of a large number of professional technicians and home users.

From basic to advanced: a comprehensive understanding of the application of drywall screws

Don't look at a small dry wall screw inconspicuous, in fact, its use is far more extensive than imagined. In addition to the installation of common hanging frames and chandeliers, it can also be competent for cabinet suspension, curtain track fixation and even ceiling keel connection. As long as you master the correct method of use, it can be seen in almost any operation scene that needs to be firmly attached to a non-solid wall.

A good helper for efficient construction: how to select high quality drywall screws?

The drywall screw brands on the market are complicated and the quality is uneven. It is recommended to give priority to carbon steel products with moderate hardness and anti-rust treatment (e. g. galvanized), and pay attention to matching the required length specifications and driving mode (cross groove or PH plum). High-quality drywall screws are not only screwed smoothly and not easy to slip, but also can resist the influence of oxidation and corrosion environment for a long time.

More than just solidity: a surprise from drywall screws

Many people mistakenly think that drywall screws only focus on load-bearing capacity. In fact, they are also excellent in details. For example, some models are equipped with special gaskets to prevent excessive depression of gypsum board; some are designed with limit rings to help control the depth of burial... These intimate small improvements greatly enhance the convenience of later repair work and the beauty of the finished product.

the secret of the sharp weapon of home DIY talent: the secret of easy installation

even novice xiaobai can complete accurate operation through a few simple steps: first confirm whether the target position is a hollow wall; Then select the appropriate electric drill accessories and set the appropriate torque level to start screwing in until the head sinks slightly to stop pressurizing. Remember not to press too hard to avoid structural damage ~

the ultimate challenge of wall fixation: there are some clever ways to solve common problems

what should I do if the old base is unavoidably loose when the old house is renovated or partially repaired? try upgrading the reinforced expansion drywall screw! This kind of special variety of built-in expansion mechanism can automatically expand when contacting the inner wall of the cavity to form a stronger grip, even in the face of seriously damaged concrete honeycomb area is still as stable as Mount Tai.

Drywall screws vs traditional screws: Who is the real performance king?

In terms of versatility, both have their own advantages, but in specific areas, especially for modern fabricated residential systems, drywall screws are clearly more advantageous. Compared with traditional metal bolts that must rely on pre-drilled positioning, the former eliminates the cumbersome preparation process while also greatly reducing the risk of dislocation rework, and truly realizes a plug-and-play-like efficient operation mode.

Environmental protection and durability: the road to quality innovation for modern drywall screws

As the concept of green building materials is deeply rooted in the hearts of the people, more and more manufacturers begin to pay attention to the sustainable development of products. The new generation of environmental protection series dry wall screws are generally manufactured by chromium-free passivation coating technology, which reduces the total emission of harmful substances on the basis of ensuring long-term anti-corrosion performance and fully meets the requirements of current international mainstream certification standards.

Great reward for changing application scenarios: witness the magical moment in space transformation

whether it is the re-planning of partition layout in commercial office areas, or the addition of shelves and even the theme decoration projects of children's rooms in the home environment, dry wall screws can always be seen silently playing a key role. In particular, some high-end custom furniture companies regard it as one of the core components to achieve modular assembly solutions to be widely used.

Save time, money and worry: an analysis of the value of long-term benefits from one investment

Although the price of a single piece may be slightly higher than the regular fasteners by several multiples, but in the long run this investment is definitely worth it. Because once the correct installation is in place, the maintenance cost is close to zero without frequent replacement, and more importantly, the resulting safety factor improvement far exceeds the economic return brought by the initial procurement expenditure itself.